Sewing Needle Guide | For Hand Sewing and Sewing Machines

Today we have a handy sewing needle guide for you. Whether hand sewing or using a machine, choosing a sewing needle compatible with your fabric and thread is crucial for a well-sewn garment. This article will explore various types of hand and sewing machine needles, their respective purpose, and how to choose the right needle for your sewing project.

HAND SEWING NEEDLES

Hand-sewing needles are used for various hand-sewing projects, including mending, beading, and embroidery. Available in various sizes and shapes, these needles are chosen based on the type of fabric and thread being used for the project.

Even with a sewing machine, certain details require the precision and the art of hand sewing. These tasks include adding bias binding to quilts, attaching buttons or trims to garments, basting layers of fabric together, and mending jeans and other garments.

Hand-sewing needles range from thin needles used for beading to very thick ones used for tapestry and upholstery.

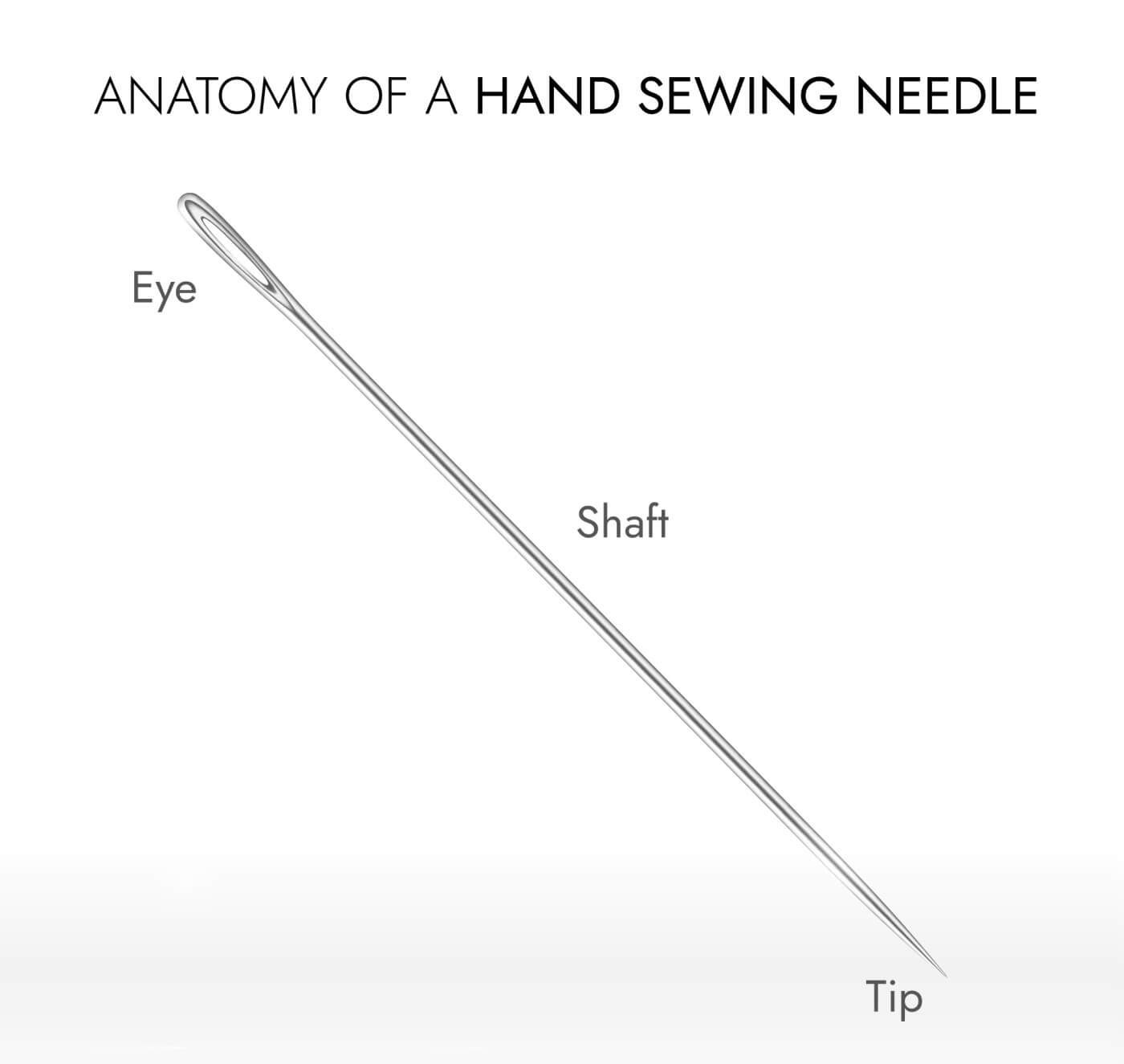

Anatomy of a Hand Sewing Needle

Before getting into the specifics of different needle types and their respective uses, let's first discuss the three features of a hand-sewing needle:

- Point/Tip (the pointed tip of the needle that pierces through the fabric)

- Shaft (body of the needle)

- Eye (the hole that the thread is fed through)

Each of these features can vary significantly depending on the intended sewing purpose. It's important to note that needles are subject to wear and tear over time. They can bend, break, or become dull with prolonged use.

How to choose the right sewing needle for your project?

When choosing a handing sewing needle for a project, it’s important to focus on:

- Needle size and needle length. As a rule, a larger number in the packaging means that the needles are short and thin. A smaller number means the needles are thicker and longer.

- Type of tip/point – The tip or point of the needle indicates the type of fabric it's suitable for. For example, needles with sharp points are versatile and suitable for use on woven fabrics. On the other side, needles with ballpoint tips are designed specifically for knits, ensuring minimal damage to the fabric.

- Eye shape – If the project requires a thicker thread, you won’t be able to use a needle with a small eye. Therefore, a needle with an appropriate eye shape is chosen based on the thread requirement. Usually, a small eye and a thick thread end up in thread fraying and difficulties in threading the needle.

As long as you have defined your project details, choosing the right needle should not be difficult. Based on the chosen fabric and thread, you first define needle size and length (thinner fabric= thinner needle), then choose the point that matches the fabric and an eye suitable for the thread.

Common Hand Sewing Needles Types

Sharps vary in size from 1 to 12 and are commonly used for garment mending, sewing appliques, or any emergency sewing. They are thin with a very sharp point, which makes them ideal for precise sewing. However, due to their delicate nature, they can break easily, making them less suitable for specific projects such as embroidering.

Ball Point needles are available in sizes ranging from 5 to 10, and feature a rounded point specifically designed for use with knit fabrics and other stretchy materials. They’re specially designed not to pierce the fabric as sharps do, which reduces damage to the fabric, especially for delicate thin knits.

Embroidery needles, also known as crewel needles, come in sizes from 1 to 10. They are characterized by their sharp points and elongated eyes. The sharp point allows precise piercing through the fabric, while the long eye accommodates multiple strands of embroidery thread or specialty threads.

Beading needles feature a round eye and a fine point. They’re designed to easily thread beads onto cords or wire. Beading needles come in sizes ranging from 5 to 10, with the choice of size often dependent on the type and size of beads or sequins used.

Leather needles are specifically crafted with long, sharp points to pierce through leather and suede without causing excessive friction or damage. By reducing friction, leather needles ensure smooth and precise stitching, allowing for professional-quality results in leatherworking and similar projects.

SEWING MACHINE NEEDLES

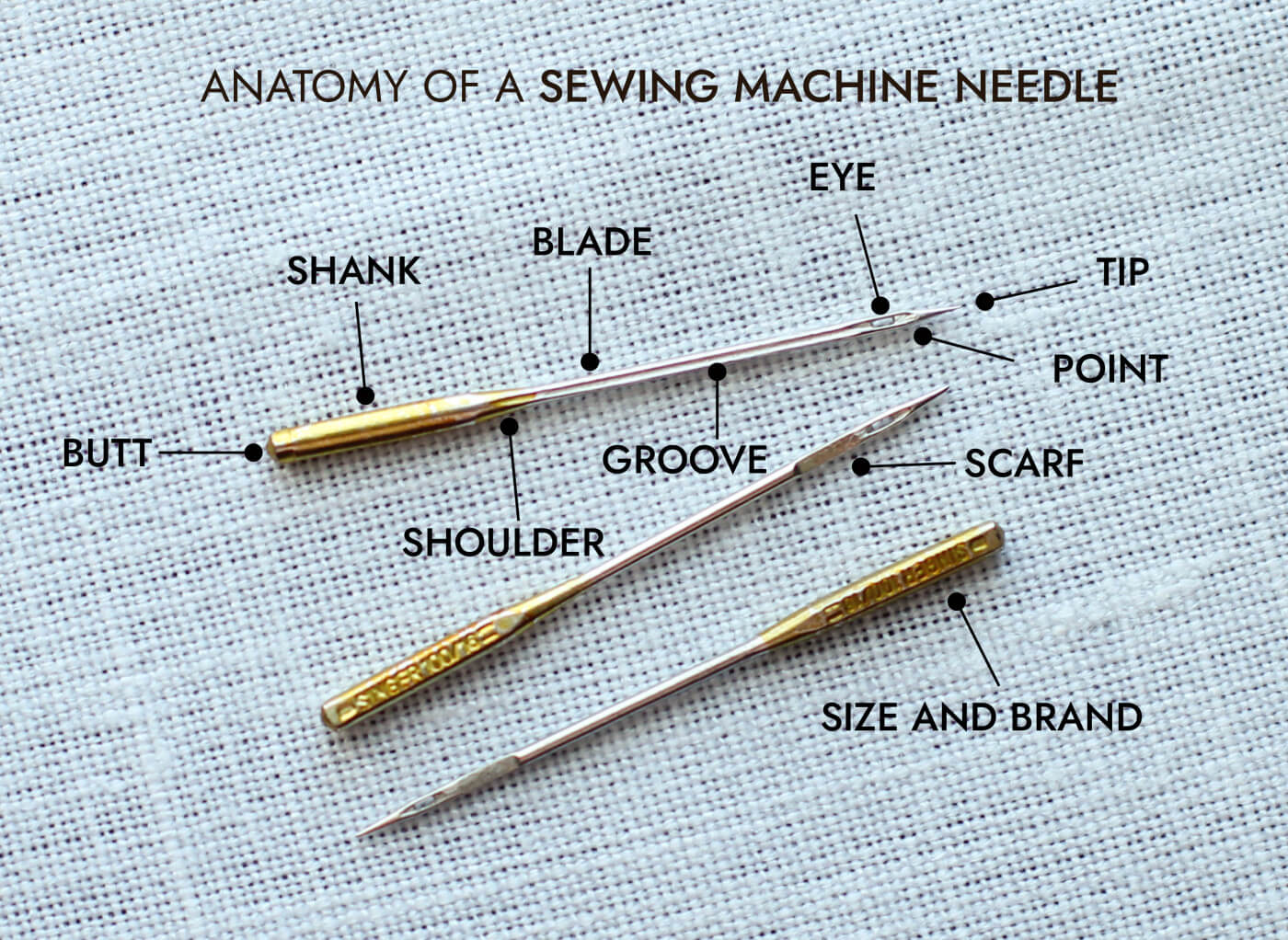

Sewing Machine Needle Anatomy

Needle Size Systems

Metric Needle Size System (NM)

Needle sizes in this system range from 35 to 200 and increase by 5 or 10.

American Needle Size System (IMPERIAL SYSTEM)

American needle sizes range from 2 to 25 and increase by 1 or 2.

The NM “Number metric” indicates the diameter of the needle blade in hundredths of a millimeter. For example: a sewing machine needle with a blade diameter of 0.90 mm corresponds to NM 90 (14 US Size) and a needle with a blade diameter of 1.30 mm to NM 130 (21 US Size).

Depending on the brand, you may come across needles labeled with either European or American sizing or both. It's essential to understand these numbers before making any needle purchases.

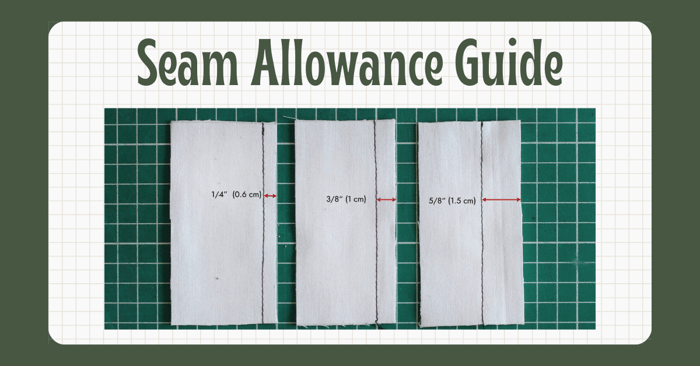

The comparison table below shows the corresponding needle sizes on both systems, along with suggested fabric types:

Diameter | NM Size | US Size | Fabric Types |

0.60 mm | 60 | 8 | Fine fabrics such as silk, chiffon, organza, lace |

0.65 mm | 65 | 9 | |

0.70 mm | 70 | 10 | |

0.75 mm | 75 | 11 | Lightweight fabrics such as cotton, heavier silks, Lycra, spandex |

0.80 mm | 80 | 12 | |

0.90 mm | 90 | 14 | Medium-weight fabric such as velvet, linen, muslin, knits, fleece |

1.00 mm | 100 | 16 | Heavyweight fabrics such as denim, leather, canvas |

1.10 mm | 110 | 18 | Heavyweight fabrics such as heavy denim, faux fur, upholstery fabric |

1.20 mm | 120 | 19 | |

1.25 mm | 125 | 20 | Extra heavy fabrics |

1.30 mm | 130 | 21 |

Sewing Needle Selection

Once you’ve familiarized yourself with the needle anatomy, sizes, and brands it’s time to choose the right sewing needle one for your project. Initially, this may appear daunting, especially for beginners. However, understanding these details is crucial for achieving professionally constructed garments.

Similar to hand sewing needles, choosing the correct sewing machine needle revolves around two key considerations: the type and weight of the fabric and the type of thread being used for the project.

For example, for a denim tote bag, you will need a needle that is specific for denim fabric (depending on the weight of the denim, the sizes vary from 90 to 130 NM) and compatible with a highly durable thread used for sewing with denim. Remember that certain topstitching threads for denim are quite thick and are mainly used for decorative stitches.

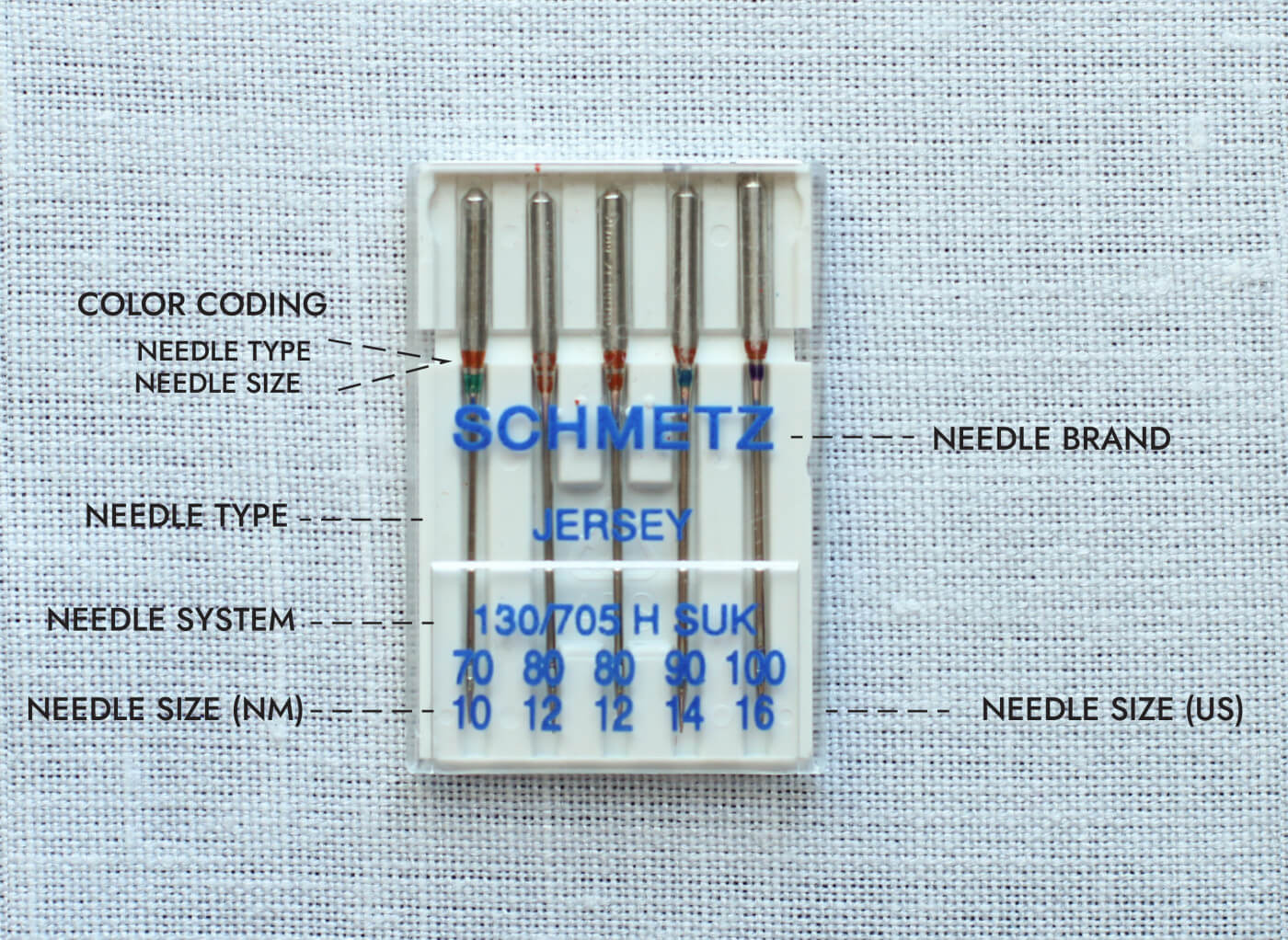

How to Read a Needle Package

Reading a needle package correctly provides valuable information about the needle's specifications and suitability for your sewing project. Some of the details typically found on a needle package include:

How often should you change the needle?

A general rule of thumb is to replace the needle after eight hours of sewing, but with experience, you’ll notice when it’s time to change it. As you sew, the needle points get dull, and the body/shaft may bend depending on the fabric you’re using and whether you’re sewing with pins.

A visual inspection helps to determine whether the needle tip and shank are still good. Even with that, skipped stitches, seam puckering, damaged fabric, or noises that are not normal for the machine are some of the clues that it is time to change the sewing needle.

Sewing Machine Needle Types

General Purpose Needles

Universal needles feature a slightly round point that allows them to penetrate woven fabrics effectively without causing damage. They come in various sizes, such as 60/8, 65/9, 70/10, 75/11, 80/12, 90/14, 100/16, 110/18, 120/19, twin, and triple.

Jersey (Ball Point) needles feature a medium ball point and are used on knits and some stretch fabrics. The medium ball point does not break into knit fibers but goes smoothly through it. These needles come in various sizes, such as 70/10, 80/12, 90/14, and 100/16.

Stretch needles feature a medium ballpoint with special features to prevent skipped stitches on stretch fabrics such as high-elastic knitwear. They come in various sizes, such as 65/9, 75/11, 90/14, and twin needles.

Specialty Needles

Jeans/Denim needles feature a medium ballpoint with a reinforced blade and are used primarily on denim and fabrics of similar weight. They are designed to penetrate extra-thick fabrics without the risk of skipped stitches and broken needles. They come in various sizes, such as 70/10, 80/12, 90/14, 100/16, 110/18, and twin needles.

Leather needles feature a cutting point and are used on leather, artificial leather, and heavy, non-woven synthetics. They come in various sizes, such as 70/10, 80/12, 90/14, 100/16, and 10/18.

Embroidery needles feature a light ball point, wide eye, and groove and are used with polyester, rayon, or special embroidery threads. They have special features that allow professional decorative stitching without skipped stitches. These needles come in various sizes, such as 75/11, 90/14, and twin.

Quilting needles feature a special taper to the slightly rounded point. They are made especially for machine quilting to allow easier fabric penetration through layers and maintain straight stitches. These needles come in sizes such as 75/11 and 90/14.

Topstitch needles feature elongated eyes and are designed to achieve straight stitch lines when using regular or heavier topstitching threads. They come in sizes such as 80/12, 90/14, and 100/16.

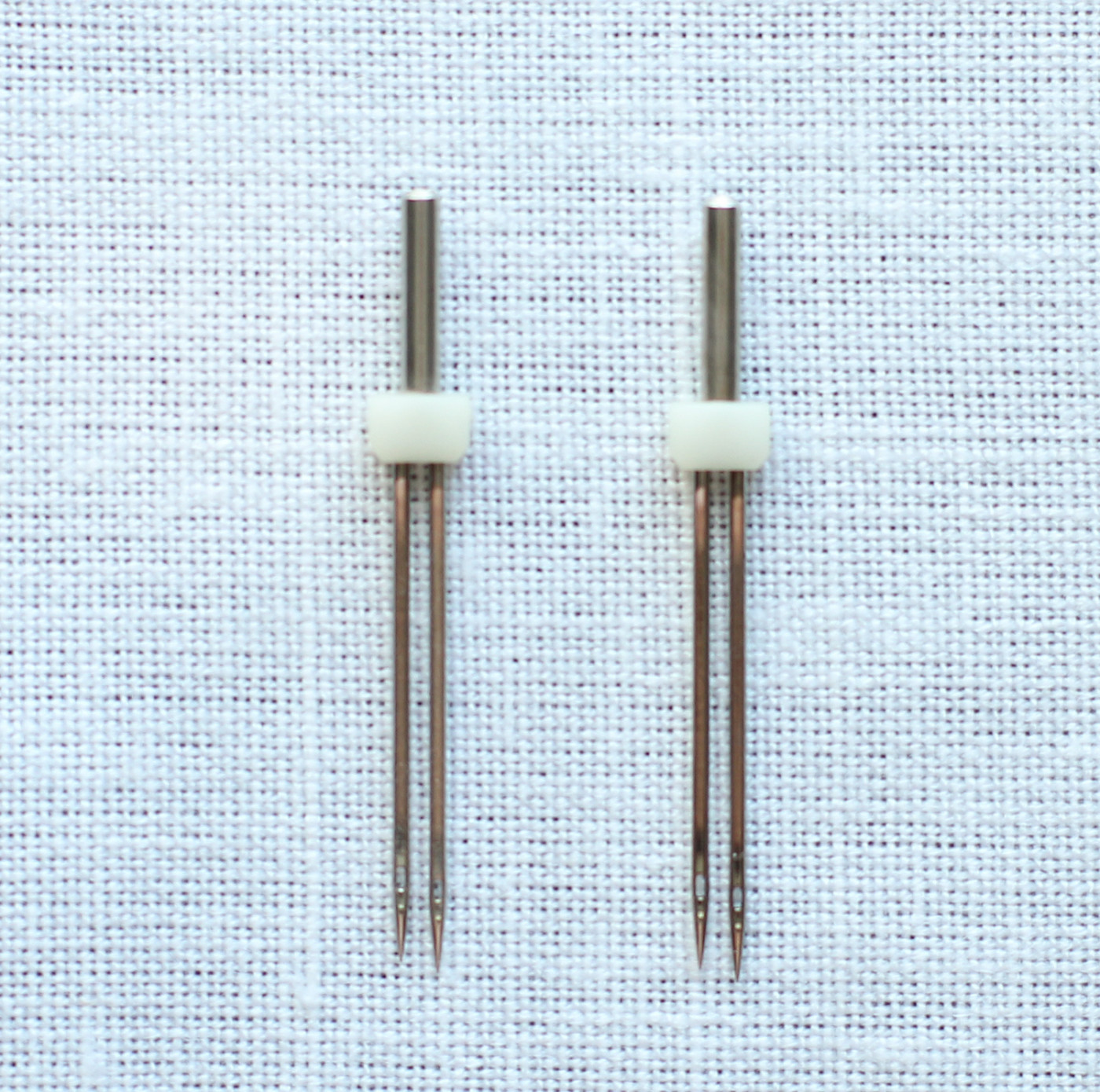

Multiple Needles

Twin needles feature two needles mounted on one shank and are used to create two rows of stitches simultaneously. Two spools of thread are needed for the twin needle. These needles are available in universal, ballpoint, stretch, jeans, embroidery, and metallic types.

Triple needles feature three needles mounted on one shank and are used to create three rows of stitches simultaneously. Three spools of thread are needed for the triple needle.

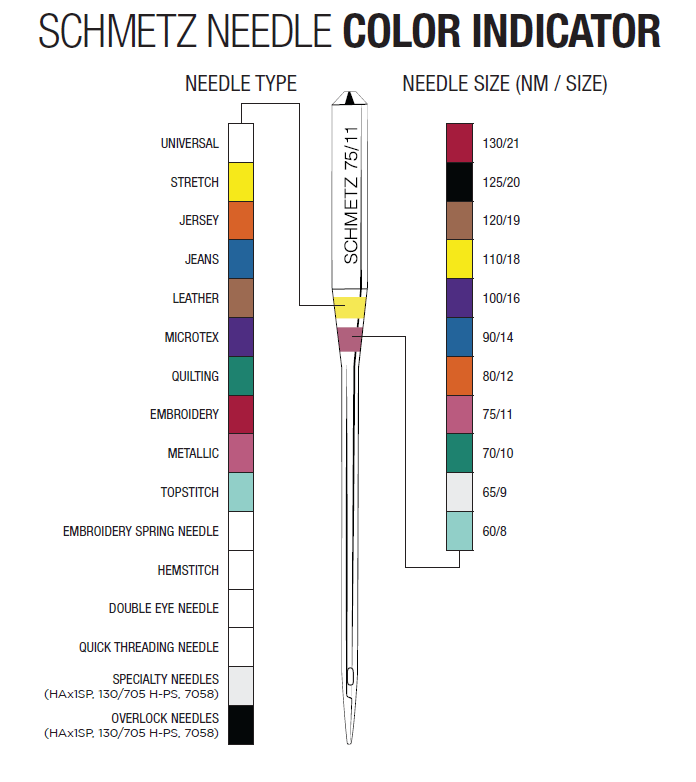

Sewing Machine Needles Color Coding

Nowadays, sewing machine needles for household purposes have two colored bands. The top band indicates needle type, and the lower band indicates needle size.

The brand assigns these color codes, which can vary between needle manufacturers. Refer to the packaging to ensure you understand the specific color codes used by the brand of needle you're using. While some brands may adopt standardized color coding, others may have unique color schemes.

For example, the following sketch, sourced from the SCHMETZ website, demonstrates the significance of each color band.

A final thought on sewing machine needles

Do not sew with bent needles, and if your sewing keeps breaking needles, make sure to check the following:

- Does your machine need cleaning or maintenance?

- Is the needle type and size correct for your chosen fabric?

- Is the thread thickness compatible with the chosen needle?

- Is the thread tension set correct?

- Are you using the correct sewing foot and sewing technique?

We all make mistakes, but taking some time off and reflecting on the problem is always helpful rather than trying to fix everything in a moment of frustration.

Thank you for joining us today! Before you leave, make sure to sign-up for our newsletter below. You can also join our Facebook Group or follow us on Instagram. Happy Sewing!